THE IMPORTANCE OF THE PRINT TEMPLATE

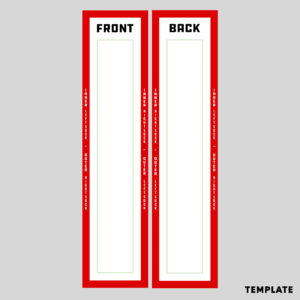

The socks are printed on the front and back through the sublimation process. Because of this, it is important to understand/use the print templates provided within the app to ensure the final product is created to your expectations. If you do not follow the template correctly, we cannot guarantee certain aspects of your design will show up on the final product.

When using the template to create your artwork, pay close attention to the Safe Zone. The safe zone is denoted by the green box. The most important aspects of your design should remain within the safe zone to ensure they are printed on the final product. Anything outside of the safe zone runs the risk of getting trimmed off.

The red Bleed Area represents the edge of the product and then some. Since the socks are printed by hand, it is important to extend your artwork all the way through the bleed area. The bleed area will likely not show on the final product but if you do not have any artwork/color/texture you run the risk of having blank (white) portions that appear on the sock. Bleed areas within print templates are in place as a preventative measure in case of errors that can occur in the printing process.

EXPECTATIONS

The sock designs are NOT sewn on. The designs are printed. Understanding this will help temper certain expectations about the product. The socks are less of a fashion accessory and more of a novelty product because of this. Although the socks are a great product, they do not come without their drawbacks in comparison to popular custom sock brands such as Stance. We want to be transparent about our products, so we have provided examples of what the real sock looks like in all stages. Please see the examples below. (The socks are stretched to maximum capacity on the mannequin to provide you with a more extreme example.)

You will notice that once worn/stretched, the socks display some faint white markings. This is due to the blank sock being white. The socks are printed flat which unfortunately allows for white fibers to show through when worn/stretched. You will also notice the side views show overlap of the print causing a noticeable seam. This, again, is caused by the flat printing process. There is a two step printing process where the front of a sock and back of the other sock are printed at the same time. Once printed, the socks are flipped over and the process is repeated. This can cause excess ink to overlap and leave a darker, more noticeable, print along the side profile of the socks. We try our best to create the most accurate mockup images for our users as we can, unfortunately we cannot always replicate imperfections and printing issues caused by human error. Please keep this in mind when creating and selling custom printed products.

SUBLIMATION PROCESS

The socks are products that get printed through the sublimation process. During the sublimation process, inks are heated to a gaseous state which enables the print to sink into the product pores. When the temperature drops, the ink returns to a solid state and becomes a part of the product. This process allows for longer lasting and more durable prints.

DESIGN TIPS

Knowing the print process helps with creating your designs. Typically sublimation reproduces prints quite accurate to the file you submit to our app. However, there are a few things to keep in mind to ensure your design prints to your satisfaction.

1.) Drop-Shadows: Drop-Shadows help add depth and dimension to designs, but they do not always play nice in the sublimation process. Often times drop-shadows tend to bleed into other aspects of the artwork making the final product look less than ideal in comparison to the uploaded design file. One way to combat this is by using halftones. Halftones are varying sizes of solid color dots that give the illusion of gradients while applying solid color rather than fading from dark to light opacity like you would find in a drop-shadow.

2.) Low Opacity Elements & Blending Modes: Using varying opacities and blending modes helps designs appear more dynamic and, in some cases, more realistic. The sublimation process can blend these effects further than your liking. We suggest erring on the side of higher opacity and blending items to be brighter than what you would prefer on your computer screen. For example, if you like the way your graphic looks at 15% opacity, we would suggest increasing the opacity to 25%-35% so it is not lost on the final print.

3.) Print Accuracy & Expectations: The accuracy of sock prints differs from many of our other sublimated products. Socks are a product that are three dimensional but are printed flat on the front and back. Because of this, the socks may not always appear seamless on the sides. It is important to understand this as the feature graphic will be displayed on the front and back rather than the sides of the sock.

The print process is done by hand so matching up the front and back designs is not always 100% accurate. This means designs that flow from front to back will likely not match up exactly. We strongly recommend using patterns or abstract designs to help combat the inaccuracies in the printing process.

4.) The Bolder The Better: Bolder design elements tend to look the best with socks. Since the print is done while the socks are flat, thinner designs can get lost once worn by the customer. To avoid loss of detail, we recommend opting for bolder design choices so the print is still impactful while on the feet.

5.) RGB vs CMYK: Knowing your color codes may be the most important practice when using Print on Demand. RGB (Red, Green & Blue) is the color code for web applications. CMYK (Cyan, Magenta, Yellow & Black) is the color code for print applications.

We ask that our users upload artwork in RGB because they are uploading a graphic to the web. We strongly recommend checking the files in CMYK prior to upload because the graphic uploaded in RGB will be converted to CMYK at the print facility. DO NOT upload artwork to the app in CMYK – this will cause issues with how your design colors are represented on the mockup images. Upload your artwork in RGB, but check your file in CMYK first and adjust accordingly.

Some colors are created specifically for your screen using RGB. We call these backlit colors as they are using light from your computer monitor to add more intense vibrancy that cannot be reproduced in the printing process. This is why we always recommend checking your files in CMYK before uploading because there can be drastic shifts in color that completely change what is shown on your mockup image versus the final product. Please see the example below.